Top Automotive Wire Harness Manufacturer You Can Trust

Vehicles need the most reliable wire system for power and smooth signals. A top Automotive Wire Harness Manufacturer offers the most reliable harnesses and the most friendly service for the customers. You will get the exact type of harnesses for your project. The size and the designs are always accurate according to your details. The parts used in the harness are selected carefully to ensure durability. For the errorfree performances these parts are accurately attached according to your designs. You can always have the smooth and best performances from these wire harnesses. Top Automotive Wire Harness Manufacturer If you need a top Automotive Wire Harness Manufacturer, QL-Custom Technology Ltd. is a name you can trust. This company manufactures robust, high-quality wire harnesses and OBD Y Splitter cables that ensure cars remain safe and operate efficiently. Their harnesses help cars run smoothly and stay connected for a long time. Every product is carefully designed, thoroughly tested, and built to withstand demanding driving conditions. Car makers, repair shops, and technicians rely on these products to keep vehicles running smoothly every day. Smart Custom Automotive Wire Harness Manufacturing QL-Custom Technology Ltd. is one of the world's largest automotive wire harness manufacturers of automotive wire harnesses. They create strong and easy-to-use products that last. Their automotive wire harness manufacturing process follows a clear set of steps, from initial design to final testing. Each harness is thoroughly tested for strength, heat resistance, and flexibility to ensure it performs effectively in real-world driving situations. Each custom automotive wire harness is designed to fit a wide range of vehicles, from small cars to large trucks. The company also makes special OEM automotive wire harness systems for car brands that need unique designs. No matter how big or small the order, they always promise top quality and...

Read More »Expert Custom Wire Harness Designs for Any Project

In your project wire systems are the most essential part. Custom wire harness designs are especially made for keeping the main wires safe and error free. These are the ideal items for daily use. These harnesses are made with the most advanced quality items which makes them the exact choice for your project. The harnesses are expertly designed to save power and keep the operating system running smooth. These are carefully manufactured to supply the power and smooth signals to the control panel. The base of the harness is made with the materials that can resist the tough weather. The core of the harness stays safe and produces secure links every time with the machine. Expert Custom Wire Harness Designs for Any Project At QL-Custom Technology Ltd., we carefully make all the custom wire harness designs. We use the proper skills and smart machines to create, design and manufacture the harness. We provide the most advanced harnesses made with the best quality materials to keep the harness secure. We test all the parts and then use them to make the harness. We provide you the most suitable price for the harness and offer you the premium quality services. The leading harness companies worldwide select us because of our top quality products and the service quality we offer. We had enough experience in producing the best and accurate service to various sectors. Pick Our Custom Wire Harness Design Services Our custom wire harness design services global team helps customers everywhere with safe, strong, and flexible designs. We manufacture harnesses that accommodate a wide range of tools and machines, ensuring your work remains smooth and secure. We design custom auto wiring harnesses, low-voltage wire harness designs, and industrial cable harness solutions to enhance your systems. We also make a prototype custom wire...

Read More »Buy Custom Wire Harness Assembly with Expert Design

A custom wire harness assembly is the most essential part to keep the wires and the other vital parts in a place. Loose cables can cause errors to the machine system. And because of this harness you will find no issues with your machine system. When you buy a customized wire harness that means you are getting the exact size for your machine. The parts are very durable and high quality which makes them long lasting. These are designed to last for many years. The main wires and the connectors are made to smoothly deliver the electricity and accurate signals every time. Why Choose Custom Wire Harness Assembly When you want your machines or tools to run safely and smoothly, a Custom Wire Harness Assembly is a perfect choice. It connects every wire and part in the best and safest way. A custom cable harness keeps all your wires neat and protected, so they don’t break, twist, or cause problems. This helps your system function more efficiently and last longer. Each custom wire harness is designed specifically for your needs, featuring no extra wires, minimal mess, and clear functionality. Whether you use it in cars, trucks, factories, or at home, it delivers clean power and consistent performance every time. These harnesses are rigorously tested to withstand heat, pressure, and everyday use, ensuring they remain strong and safe for years to come. A custom wire harness makes work safe and straightforward. It keeps wires in order and helps power flow smoothly. It also makes repairs easier and faster. When each wire is grouped and labeled clearly, your setup appears clean, and your work is completed quickly. A strong custom wiring harness gives you a safe, simple, and innovative way to manage your system. Benefits of Custom Made Wiring Harness A...

Read More »Buy Our Automotive Wire Harnesses to Get Accurate Usability

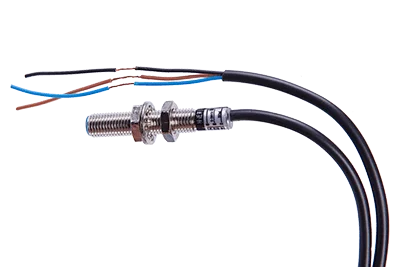

Our automotive wire harnesses are carefully made with best quality materials and suitable for various kinds of sectors. We carefully check every harness before supplying the final product to you. For better power supply and exact signal to the control panel and vehicle engine these harnesses are the ideal choice. You always get the best results and accurate usability from these harnesses. In rough condition these harnesses can resist dirt and other harmful elements. These harnesses are designed to last for a long time. We carefully connect each wire and the clips to the harness for high usability. Simple Upgrade for Stronger Performance If your car's wiring is old, weak, or not functioning correctly, consider our automotive wire harness upgrade. It helps your vehicle start faster, use less power, and run smoothly. Our harness connects your car systems the right way and keeps every part safe from damage. We include a simple automotive wire harness installation guide that anyone can follow, even if you have no prior experience with wiring. You can easily install it at home or take it to a repair shop for professional assistance. automotive wire harnesses fit both factory systems and automotive wire harness aftermarket setups. After you upgrade, your lights, sensors, and engine will all function more efficiently. It saves you repair time and makes your car feel new again. This harness helps your vehicle stay safe, strong, and ready for every trip. Made for Accurate Engine Work The automotive wire harness for engine is built to handle heat, oil, and vibration. It provides steady power to your engine, ensuring it runs smoothly every time. Each harness uses strong automotive wire harness insulation types that stop burns, cracks, or short circuits. The materials are thick, safe, and made to last. Every part is designed to...

Read More »Stay Ahead of the Curve with Our Automotive Wire Harnesses

There are many cables in automotive wire harnesses. These cables are the main path that supplies the control system and the engine exact data and power supply. The wires are separately designed for its sectors. We carefully manufacture and supply you the exact harness for your needs. We carefully test each harness for your vehicle system. We use the high quality and carefully tested materials for your harness so that your vehicle stays safe and provides you the best service every time. Benefits of Selecting Our Automotive Wire Harnesses We make automotive wire harnesses that are easy to link with various types of vehicle systems. Each part of the harness is accurately designed to provide the exact flexibility and durability. It stays strong even when your car shakes or moves over rough roads. Whether you need wiring for your car's lights, dashboard, or your automotive wire harness for engine, we make it fit perfectly. With our automotive wire harness installation, setting up the system is simple and straightforward. Benefits: Long life and steady power flow to all parts Quick and straightforward to install with clear steps Safe insulation that protects every wire Works with new and old cars easily Stays strong in heat, rain, and cold Complete help with automotive wire harness repair and upgrades Every harness is checked by skilled workers so that you receive the exact quality harness according to your need. Smart Automotive Wire Harness Design We make our automotive wire harness design smartly so that the harness becomes easy to use and install. We label the cables and the connectors exactly according to the sizes so that the harness fit the automotive system perfectly. We simply and smartly design the whole process to create your wire harness Accurately. Features: Clean layouts that make wiring...

Read More »Purchase Top Level and Reliable Custom Wire Harness from Us

We manufacture custom wire harness smartly and carefully to ensure the top level durability. The wires and the other materials we used in the harness offer the most durability and flexibility. We check each part of the harnesses to ensure that the parts are correctly attached. You can select the harness size and the designs so that it can fit your project accurately. These are made for ease of use. We make the harnesses that are easy to bend and can easily fit to your project. We are a leading supplier of custom wire harness assemblies all over the world. The harnesses are easy to install and last for a long time. With these harnesses you always get the smooth power and signal supply. Get a Clear Custom Wire Harness Cost Estimate You can always ask us for a custom wire harness cost estimate before making a purchase. We make prices clear and easy to understand. Our custom wire harness quoting process is quick. You can choose wire length, connector type, and wire cover style. In our custom wire harness shop, you can order large or small batch custom wire harness builds. If you'd like to test first, we can create a wire harness prototype for you. We will guide you through every step. Our team listens to your ideas, answers questions, and gives full support. We care about every customer and ensure you receive the correct harness for your project. We promise a smooth order process and friendly help every time. Custom Wire Harness for Electronics and Robotics Our custom wire harness for electronics helps devices work safely and smoothly. Each wire is made to fit your product's shape and size. We use clean copper and thick insulation to make it strong. The custom wire harness for robotics we...

Read More »Expertly Crafted Custom Wire Harnesses for Your Applications

We manufacture each custom wire harness exactly according to your needs. We follow the most secure and smart steps to make your harness for your system needs. We select the best and high quality materials to make the harnesses accurately. The harnesses are checked carefully many times before we ship it to you. There are many categories of harnesses we supply for various types of sectors. Our harnesses are perfectly sealed so that the harness can resist the rough weather. Our main aim is to provide you with the best quality products according to your needs. Trusted Custom Wire Harness Manufacturer As a leading custom wire harness manufacturer, QL-Custom Technology Ltd. produces robust, safe, and user-friendly harnesses for cars, trucks, and large machinery. We also make custom waterproof wire harnesses that work perfectly even in rain, dirt, or heat. Every harness we make is designed to fit your system and tested before shipping. Our team thoroughly checks every wire and connector to ensure everything is in perfect condition. Each custom wiring harness build gives steady power, fast signals, and smooth operation. With our harnesses, you can prevent breakdowns, save on repair time, and extend the life of your machines. When you choose us, you get a product crafted by experts who care about every detail and are committed to your complete satisfaction. Top 4 Recommended Custom Wire Harnesses We also manufacture cables that enhance your car's sound, power, and control. Each cable type serves a specific purpose, helping your system function optimally. 1. Custom XLR Cable Custom XLR Cable is designed for use in car audio and communication applications. It blocks noise and gives clear, clean sound. The metal shell protects it from bumps, and the soft coating keeps it safe from wear and tear. These harnesses are made with...

Read More »Shielded Custom Wire Harness for EMI-Sensitive Electronics

For the smooth and best use of EMI-sensitive electronics use shielded custom wire harnesses. These harnesses are made to accurately fit with the electronics that are very sensitive. For the exact data transfer and high power supply use these harnesses to always have the best outcome. You can use them for various sectors. The outer shield attached with the harness keeps the harness and wire core safe and they last for many times. Why Shielding is Key for Custom Wire Harness Shielding is like a cover that wraps around the wires. This cover blocks outside noise and keeps the signal inside strong and clean. It ensures signals stay steady from the start of the cable to the end. Even a small bit of noise can cause errors, freezes, or shutdowns in smart devices. Because of this, custom wire harness assembly services often use foil, braid, or both to strengthen the protection. This lowers EMI and makes the whole system run without any trouble. Shielding also helps when wires are close together, so their signals do not mix. This is very useful when a tight space and cables are packed side by side. Our Best Custom Wire Harness Flat Ribbon cable for Simple Layouts A flat ribbon cable is thin, light, and very neat. It is a good choice for places where space is small and the design needs to be tidy. This type of cable keeps signals in a straight line, so they do not cross or mix with each other. That makes them safe and clear for boards, printers, and control devices. Many custom cable and wire harnesses use ribbon cables because they bend easily, lie flat, and connect without much work. They also save a lot of space and give the inside of a device a clean, simple...

Read More »Purchase Custom Wire Harness for Top-Grade Quality

A custom wire harness is a smart way to keep cars safe, smooth, and strong for a long time. Each harness is built with care, tested with skill, and made with strong parts that pass strict checks. They are built to match car needs and give safe links that keep power flow steady. With custom harnesses, cars run with no loose wires, power loss, or breaks. They provide peace of mind to drivers, save time, and cut repair costs. They are simple to install, easy to use, and work well with any car. They are built to last many years and give safe rides every time. These harnesses help cars work better, last longer, and stay safe on all roads. Why Use a Custom Wire Harness When you need safe, strong, and simple cables for school, home, or work, a custom wire harness assembly is the best choice. It keeps all wires neat and easy to use. It also makes them last longer and stay safe. With custom wire harness manufacturing, each wire and part is shaped to fit your own needs. This saves time, lowers risk, and helps your tools work much better. A harness also makes your project look neat, pro, and clean. Suppose you want custom cable and wire harnesses. In that case, you can order ones that fit cars, machines, medical tools, robots, or even smart home devices. A harness is like a strong shield that holds all wires together to work as one safe unit. Top-Grade Quality Custom Wire Harnesses Custom XLR cable A Custom XLR cable is one of the most used cables for music and sound. It makes a clear sound and cuts out bad noise. People use it for concerts, music studios, live shows, and even at home. With china custom wire...

Read More »Automotive Wire Harnesses for High-Performance Vehicle Systems

High-performance automotive wire harnesses are made for top-grade vehicles. These harnesses connect the car parts to supply power and signals precisely. These wires are especially made to handle the heavy loads and heats. For tough and harsh conditions these harnesses are specially designed. Premium quality harnesses always keep the vehicle system in good condition. These harnesses are used in many sectors. For the smoothest performances use these harnesses. Cost Per Unit: Planning Smart The automotive wire harness cost per unit is key when building cars or trucks. The price changes by wire size, type, insulation, and number of plugs. Small and simple harnesses cost less, while large and heavy ones cost more. Buying many units simultaneously lowers the cost per piece and saves money. This is smart for shops or makers. Knowing the unit cost helps in planning budgets and making smart picks. It helps keep a balance between safe parts and a fair price. With clear cost plans, makers can build safe but not too costly cars. Available Custom Assembly Services Shops can now use automotive wire harness assembly services to save time and simplify work. These services cut wires, crimp ends, wrap them with tape, and test each piece before shipping. The harness comes ready to use right away. This helps when cars need high trust and no mistakes. Shops that use custom services do not fear wrong sizes or weak plugs. Each plug, each wrap, and each cover is tested for safety. This lowers mistakes, saves work time, and builds smoothly. OEM vs Aftermarket Harness Choosing OEM vs aftermarket automotive wire harness is a large call for car owners. OEM harness is made by the car maker, so it fits perfectly, but may cost more. Aftermarket harness is made by other makers. It is often cheaper and...

Read More »