Custom Plastic Connectors with Plastic Injection Mold

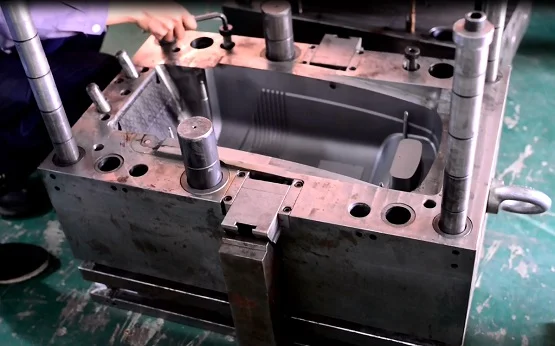

Many car parts are made from plastic. But not all plastic is strong. Weak plastic breaks. Strong plastic lasts long. Good plastic makes your car work better. Plastic molding is the best way to make strong parts. It gives each part the same shape and size. This helps the part fit better and last longer. QL-Custom Technology Ltd. makes significant plastic parts. They use strong molds and test each part. Their parts work well in heat, cold, or rain. They are safe to use in many places. Strong Plastic Parts & Connectors with Injection Molding We make strong plastic parts and connectors that last a long time. These parts are built tough and also look really lovely. We use a special method called Plastic Injection Mold to make them. This innovative method lets us turn your idea into a real plastic item. It can be big or small. You can pick the shape, size, and color. You can also choose what kind of plastic we use. From the first idea to the final part, we are here to help. The steps are fast, easy, and save you money. Every part we make is strong and matches just right. Injection Molding Is a Great Way Plastic Injection Mold is a great way to make plastic parts because it works fast and clean. It is used for many things and makes every part the same, which helps save both time and money. The moulding process begins by heating the plastic until it melts. The hot plastic is pushed into a mold and then cools down. Once it cools, it becomes a hard plastic part. These parts can be hard or soft, thick or thin. This method is suitable for making lots of parts in a short time. It makes...

Read More "What Sectors Use Custom Plastic Injection Molded Connectors

Some things need unique Plastic Injection Molded Connectors to stay together. These pieces are made very carefully to fit just right. They are super strong and last a long time. Many places need these pieces so machines, tools, and other things can work correctly. These unique pieces make sure things don’t break and stay in place. Let’s look at all the areas that need them! Vehicles Need Plastic Injection Molded Connectors to Work Cars, trucks, and buses have lots and lots of little parts inside them! molded connectors help these big machines run. They help lights turn on, doors lock, and radios play music. These small plastic parts are super special! They are light, so cars do not have to work too hard. They do not get rusty, even when it rains or snows. That means cars last a long, long time! If cars did not have molded connectors, they would break faster and cost more to fix. These little plastic parts help cars be strong and safe! Hospitals use Plastic Injection Molded Connectors Doctors and nurses use special machines to help sick people get better. Molded connectors are inside these machines to help them work! They are in heart monitors, X-ray machines, and even tiny hearing aids. These pieces must be super strong and very clean. If they were dirty or broken, the machines would not work right! That would be bad for sick people. molded connectors help doctors and nurses save lives every day! Molded Connectors are Also In smart Gadgets Phones, TVs, computers, and video games all need molded connectors to work! These small parts help buttons turn on, and screens light up. Without them, headphones would not play music, and smartwatches would not tell time. These plastic parts also stop things from getting too hot and...

Read More "